AIR CONDITIONERS MANUFACTURING

Prepared products for intensive and heavy-duty use

NAYCH air conditioners and industrial coolers or chillers are entirely designed and built at Saint Nazaire in FRANCE. Our company carries out all stages of sizing, design, testing and approval procedures. We are also heavily involved in on-site service and support for our customers all over the world.

ASSEMBLY WORKSHOP

On the manufacturing side, NAYCH carries out all mechanical assembly operations, the construction and wiring of the electrical panels and the entire refrigeration circuit. All individual test operations are supervised by production and quality managers.

- Unitary production

- Performances unitary testing

- Limits and security unitary tests

- Unitary final quality acceptance

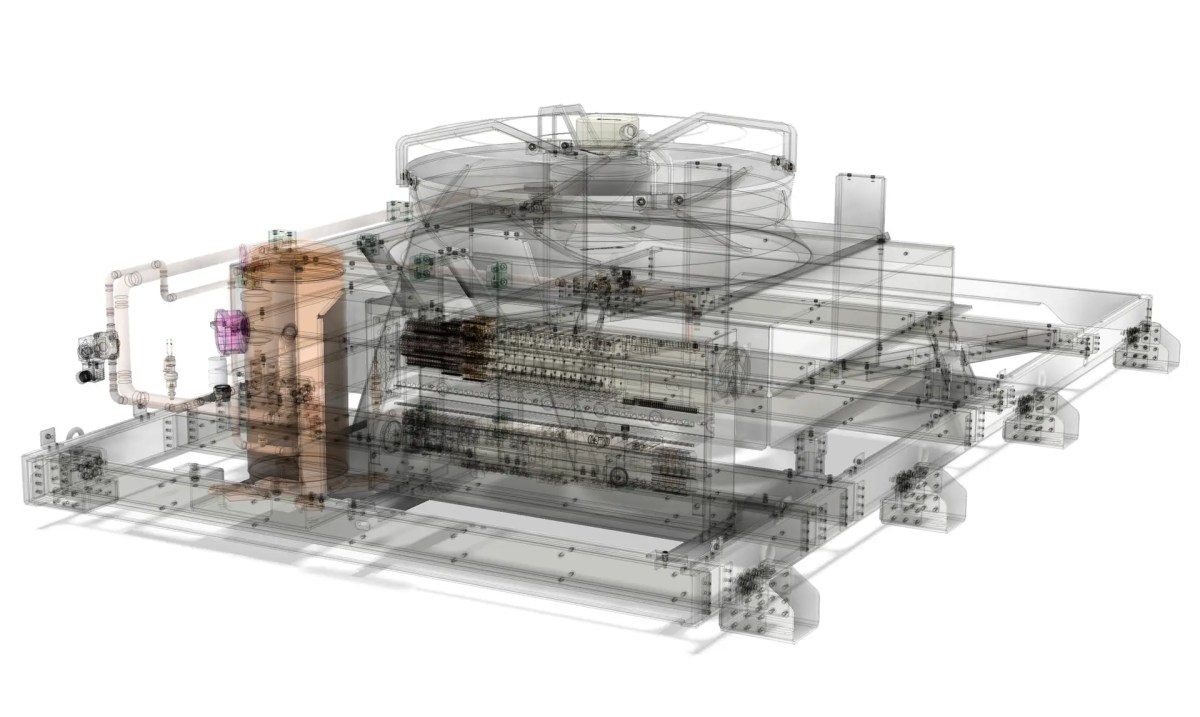

STRONG FRAME ASSEMBLY

The infrastructure frame is 100% ASI316 stainless steel, fully stainless steel riveted, with no welds to ensure optimum resistance to mechanical stress and the risk of corrosion.

PANELING THERMAL INSULATION

The aluminum sandwich panels are thermally treated with 30mm semi-rigid mineral wool, thermal conductivity 0.035 W/(m.K), fire rating EUROLASS B. Our air conditioners can withstand overpressure of over 1500 Pa.

PROTECTIVE COATING

The superstructure and body panels are made entirely of aluminum and are painted with 120-micron primer and 80-micron protective powder coating to guarantee a strong durability, classified C4H – ISO 12944:2018 (AKZO NOBEL).

CYCLONE AND DIFFICULT CLIMATE RESISTANT

The design incorporates mechanical protection of sensitive components to ensure optimum operation in the event of high winds, projectile impacts, intense solar radiation, snow and ice formation.

REFRIGERATION WORKS

Quality copper refrigerant circuit, low temperature brazed with 40%Ag under nitrogen and leak test carried out at 35 bars with hydrogenated nitrogen. Hand stripping and coating of refrigerant circuit for long-term protection.

ELECTRICAL WORKS

Our switchboards are easy to access and are made from top-quality standard components, so they can be easily interchanged if necessary. CEM – LVD compliant, UL compliance on demand.

PREMIUM METALWORKS

NAYCH designs the entire steel structure of its machines, and the structural studies determine the framework and body parts. Structural analysis includes the definition of materials in terms of quality, thickness, sheet metal manufacturing process and end treatment. Metalwork is an important part of our air conditioner manufacturing process, and a decisive factor in the performance and durability of our air conditioners. The choice to build our equipment in aluminum and stainless steel forces us to work with precision and the best processes.

TECHNICAL ASSISTANCE

All brands intervention

NAYCH provides on-site service by qualified F-GAS refrigeration technicians for preventive and corrective maintenance, as well as all commissioning operations.

- On site commissioning

- Preventive maintenance

- Corrective maintenance

- After sale and spare services

PROTOTYPING

NAYCH dedicates part of its time to creating custom prototypes for various industrial manufacturers, helping them save valuable time by providing an immediate team of experienced technicians and engineers. This team brings together all the essential HVAC expertise to ensure seamless project execution.

- Electrical and automation engineering

- Climatic and refrigeration engineering

- Filtering, ventilation and air treatment engineering

- Mechanical engineering

- Quality management engineering

DESIGN SUPPORT

We offer integrators the opportunity to save time and experience by providing design assistance that benefits from the technical advantages of NAYCH products. NAYCH industrial air conditioners were originally optimized to be easily adapted to technical containers and shelters for infrastructure or system that need to be maintained in acceptable temperature and humidity conditions.

- Long term operability

- Easy maintenance

- Specific adaptability

CLIMATE MASTERING

NAYCH Industrial Air Conditioners are equipped with a smart controller, fully configurable for optimum temperature and humidity conditions.

- External operating conditions from -20°C to 56°C

- Indoor climate control precision up to 0,1°C

- Humidity management up to 1%RH

- Configurable limits, offsets and differentials

- Customizable timers, alarms and security

Customization available on demand, please contact us.

SMART SOFTWARE

In partnership with ELIWELL, a SCHNEIDER ELECTRIC subsidiary, NAYCH has invested in research and development to obtain its own precise, fully parametric control software that combines performance and reliability. Users can manage neutral zones, proportional control bands, differentials, fan speeds, limits and more.

All values and statuses are immediately accessible. Technicians have access to pressure readings with superheat and subcooling values.

- Local and / or full remote control management

- TCP/IP Ethernet port as standard

- Modbus RTU RS485, CANbus, LON communication possibilities

CLEAN ROOM PRODUCTS

with HEPA filters

Over the years, part of our business has naturally focused on the design and manufacture of air conditioning systems that incorporate precise temperature and humidity control, along with HEPA (High Efficiency Particulate Air) filters for ISO-classified cleanrooms, capable of trapping at least 99.97% of particles that are 0.3 microns in size or larger.

PERFORMANCE TESTS

NAYCH products are individually tested through a FAT (Factory Acceptance Test) procedure lasting 24 to 48 hours per refrigeration circuit and under all operational conditions. Performance is recorded, and all settings and configurations are checked by the commissioning team. Each function, contact, or relay is tested before the machine leaves the factory.

ON-SITE TESTS PROCEDURE

On-site testing procedures are carried out using a high-capacity load bank, capable of delivering up to 500 kW of thermal power, in order to simulate intensive operating conditions for the equipment.

THE CORE TEAM

NAYCH is a team of technical experts in HVAC engineering from the refrigeration and air-conditioning industry. The team is made up of field skilled technicians, qualified and experienced refrigeration engineers, product designers and quality management experts.

Stéphane NEUVY

Founder | CEO | HVAC engineer

James BALLOT

Production Manager | HVAC engineer

Chloé NEUVY

Sales & Marketing | QMS Engineer

Join our team !

contact us here

Product engineering

Workshop production

Design assistance

Logistic and Spare

Technical support

Quality management

EXPERIENCES AND CUSTOMERS OVER THE WORLD

Over the past 30 years, we have carried out major industrial projects of all kinds, in desert, tropical, continental and polar regions around the world.

WHAT CUSTOMERS SAYS ABOUT US

Laurent F.

LF ENGINEERING - CEO

Arnaud M.

TA TECHNICS - CEO

Andreas C.

SCHOELLER AG - CTO

We can support you and help for your project ?

Got questions ? Need analysis ? Calculation advises ? Ducting integration ? integration design ?

Leave your phone number & our specialist will contact you.